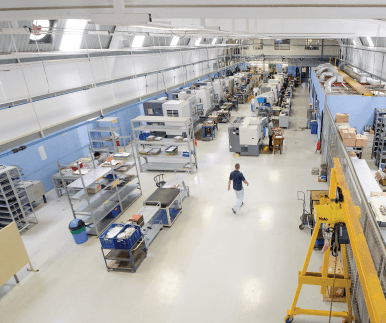

For over

20 years Preinsa

has been supplying high-precision machining parts in the metalworking

cluster for companies in the automotive sector,

ground support equipment and tooling for

aerospace, electronics and professional video applications.

Why should you do business

with Preinsa?

We are an ISO-9001 certified machine shop with focus on high precision manufacturing services to fulfill our customer specifications, with on-time delivery and at prices that produce sustainable prosperity for both partners and Preinsa.

We provide fabrication services for the manufacturing of precision parts made out of metals, polymers and castings, including heat treatments and finishes, such as paint and other electrolytic processes.

Preinsa Values

Integrity

Do what we believe is correct within the context of our mission, vision, and values.

Service

Motivation to seek the best possible outcome for those whom we serve.

Teamwork

Develop an environment that fosters collaboration and respect for others in order to achieve success for everyone.

Initiative

Actively look for opportunities to improve.

Contact Us

News

Preinsa have gotten the country brand certification "Essential Costa Rica" which is the country competitiveness label created with the aim of fulfilling the promise that Costa Rica have made to the world: the guarantee that the companies that use the country brand represent country values of Excellence, Sustainability, Innovation, Social Progress, and Costa Rican Origin.

Preinsa finished the implementation process for the AS9100D, a widely adopted standard for a quality management system required by the aerospace industry with the support of the Aerospace Cluster of Costa Rica. Audit process will be scheduled for Q2-2020.

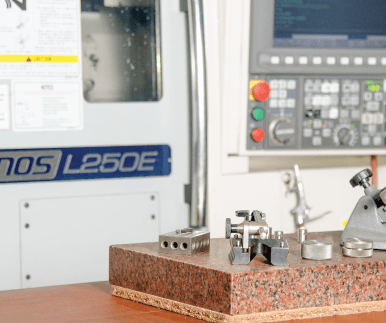

A Bridgeport V480 APC vertical milling machine with integrated automatic horizontal pallet changing

capability was bought by PREINSA at CHICAGO IMTS. This is a new generation of high production pallet

machines designed to achieve maximum capacity and performance for aerospace and automotive

industries.

Equipment features:

capability was bought by PREINSA at CHICAGO IMTS. This is a new generation of high production pallet

machines designed to achieve maximum capacity and performance for aerospace and automotive

industries.

Equipment features:

- Mitsubishi M70-4AVU control

- 20 tool changer, tool change of 3.8 second chip-to- chip.

- Spindle air purge with a speed of 10,000 rpms.

- Working surface 600 mm x 400 mm.

- Travels: (X)480 mm, (Y)401 mm, (Z) 429 mm.

- Chip conveyor hinge type.

- High pressure coolant pump which features a through spindle coolant 280 psi system.

- Renishaw wireless probe package.

- Pallet changer time of 9 seconds.